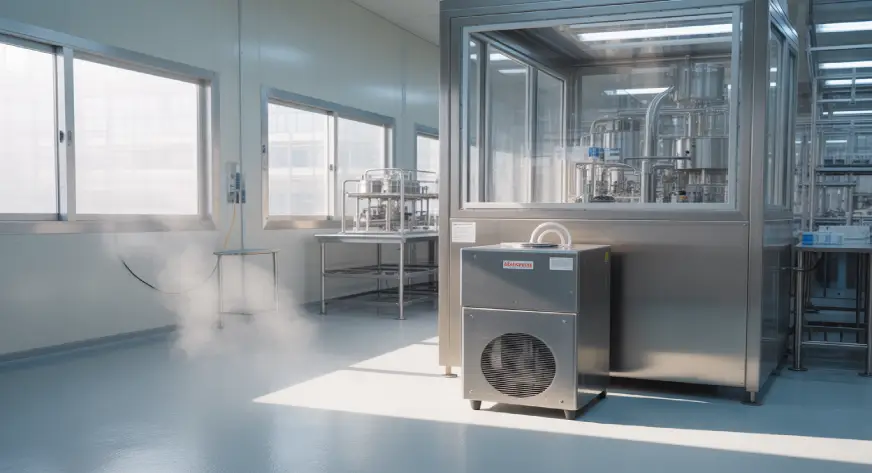

Walk into any pharmaceutical facility a tablet room, coating area, capsule filling zone, or packaging line and you’ll find one rule that never changes: humidity must stay under control.

Even a small rise in moisture can disrupt production, spoil sensitive ingredients, slow down processes, and put compliance at risk.

Pharma manufacturing is unforgiving. One batch going wrong due to excess humidity can mean huge financial losses, delays in supply, and strict quality investigations. This is why dehumidifiers in pharma are not optional — they are an essential part of achieving ideal RH levels, batch consistency, and regulatory standards.

The goal is simple: keep moisture out, keep quality stable.

Why Ideal RH Levels Matter So Much in Pharma?

Every pharmaceutical product reacts differently to humidity. Some absorb moisture quickly, some break down chemically, and others become sticky or unstable even at slightly high RH.

Common humidity-related problems pharma units face:

- Tablets become soft, sticky, or cracked

- Powder ingredients clump and stop flowing

- Capsules lose rigidity or become brittle

- Coating applications fail to dry uniformly

- Labels peel off blister packs

- Machines face rust or downtime

- Product weight variations during filling

All these issues directly impact quality, safety, and compliance.

Maintaining the ideal RH level (usually 40%–50%, depending on the process) is the safest way to keep everything stable — from raw material handling to final packaging.

This is where industrial dehumidifiers for pharma make the biggest difference.

How Humidity Affects Powders, Granules, and Excipients?

Most pharma formulations start as powders or granules, and these materials absorb moisture quickly.

When humidity rises:

- Batch consistency suffers

- Powders form lumps

- Flow through hoppers becomes uneven

- Filling machines jam

- Weight accuracy drops

- Mixing time increases

For moisture-sensitive drugs, humidity can change the chemical composition itself.

Using pharma dehumidifiers ensures powders remain free-flowing, reducing process interruptions and ensuring precise dosing which is crucial for quality and compliance.

Tablet Compression and Coating: Why Moisture Control Is Critical?

Tablet compression and coating areas are extremely sensitive to humidity.

If RH is high:

- Tablets crack during coating

- Coating sticks instead of drying

- Tablets absorb moisture and soften

- Drying time becomes longer

- Product appearance becomes patchy

A pharmaceutical dehumidifier maintains the right humidity so:

- Tablets stay firm

- Coating dries evenly

- Machines run smoothly

- Batches remain consistent

Capsule Filling: Keeping Shape, Strength, and Flowability Intact

Hard gelatin capsules are one of the most humidity-sensitive materials in the pharma world.

- Absorb moisture

- Lose shape

- Turn sticky

- Become brittle

- Deform during filling

An RH level too low is also harmful — capsules can crack.

Maintaining the right humidity zone is essential for smooth capsule filling, proper sealing, and accurate dosing.

This makes a pharma-grade dehumidifier indispensable for capsule rooms.

Packaging and Storage: Where Humidity Shows Its Darkest Side?

Even if your production is perfect, excess moisture in the packing area can:

- Damage blister packs

- Cause labels to loosen

- Promote mold around storage racks

- Affect stability of stored stock

- Reduce shelf life before the product even leaves the facility

Maintaining ideal RH levels helps pharma companies meet quality guidelines and compliance standards with confidence.

How Dehumidifiers Help Reduce Downtime and Operational Losses?

Uncontrolled humidity causes:

- Delayed batches

- Machine corrosion

- Electrical malfunction

- Dust sticking to surfaces

- Increased cleaning time

- Frequent maintenance

A pharma dehumidifier lowers operational friction by keeping conditions predictable.

The benefit is simple:

- More uptime

- Fewer breakdowns

- Faster batches

- Longer machine life

Choosing the Right Dehumidifier for Pharma Use

When selecting a dehumidifier, pharma units should look at:

- Required RH range

- Room size

- Temperature range

- Moisture load

- Stainless steel body (for hygiene)

- HEPA and washable filters

- Low noise

- Energy efficiency

- Continuous drainage setup

- Reliable after-sales support

Final Thoughts

Pharma manufacturing lives on precision — and humidity is one factor that can quietly disturb that precision every single day.

Whether it’s powders turning sticky, capsules losing shape, coatings failing, or packaging becoming weak, moisture affects everything from quality to compliance.

Using reliable dehumidifiers in pharma ensures stable RH levels, consistent batches, fewer rejections, and smoother audits.

They protect your materials, your processes, and your reputation — all while keeping your facility compliant and efficient.

Credence offers a dependable range of industrial dehumidifiers designed specifically for pharmaceutical environments. Built for hygiene, accuracy, and long hours of continuous use, Credence machines help maintain ideal RH levels across production, storage, and packaging zones. With expert guidance, free pre-sales visits, and trusted after-sales support, Credence ensures your facility stays compliant, efficient, and moisture-free.