Humidity may feel harmless, but for powdered food manufacturers, it’s one of the biggest reasons behind sudden production delays, rejected batches, inconsistent textures, and customer complaints. Even a slight rise in moisture can turn a perfectly free-flowing powder into hard, lumpy chunks, ruining product quality long before it reaches the market.

Why is Moisture the Silent Enemy of Powdered Foods?

Whether you manufacture spices, protein powders, instant mixes, flour blends, or baby food — you’ve definitely seen powders turning sticky, caked, or lumpy during monsoons or in high-humidity regions.

A powder behaves the way it does because of particle size, surface area, and hygroscopic nature. When moisture enters the mix, powders absorb it instantly. This causes.

- Lumps

- Caking

- Stickiness

- Poor flow

- Inconsistent dosing

- Higher spoilage

Most manufacturers don’t realize that these issues come from poor humidity control in food processing — not from machinery, raw materials, or packaging alone.

This is exactly why powdered food manufacturers need dehumidifiers as part of routine operations, not as a last-minute fix.

Real Problems Manufacturers Face When Humidity Rises

Here are the real, everyday challenges supervisors and facility managers report:

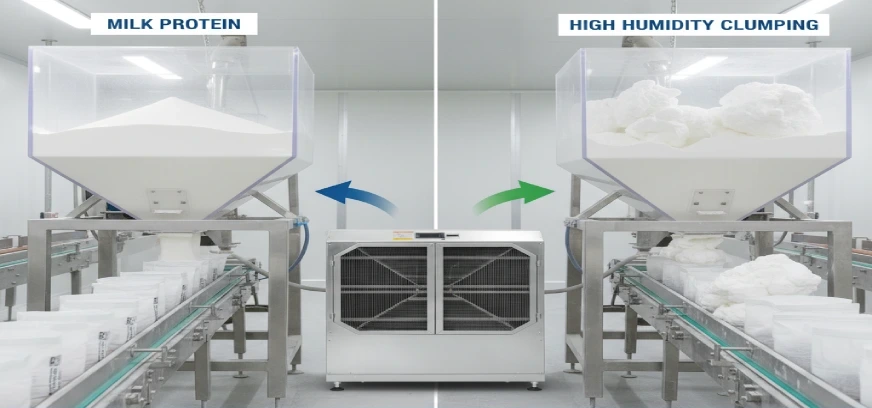

Powder sticks inside hoppers

Moisture causes powders to clump around hopper walls, making product flow uneven and slowing down filling lines.

Packaging machines jam frequently

Sticky powders block nozzles, reducing efficiency and increasing downtime.

Inconsistent weight per packet

Clumped powders don’t flow smoothly, causing underfilling or overfilling — a major compliance concern.

Reject rates shoot up

Lumpy or caked products lead to customer complaints and expensive batch recalls.

Increased microbial activity

High moisture accelerates bacterial growth, shortening shelf life.

All these issues can be minimized by maintaining the right RH levels — and this is where dehumidifiers become essential.

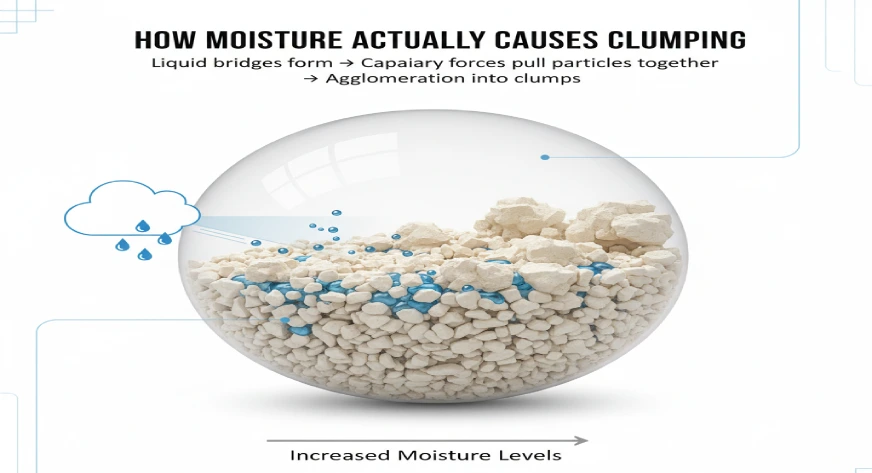

How Moisture Actually Causes Clumping? — The Simple Science

You don’t need complex scientific terms to understand this. Here’s the simple chain reaction:

- Humidity enters the air.

- Powder particles attract moisture.

- The surface becomes sticky.

- Particles join together and form lumps.

- Flow becomes restricted.

- Machines choke, packaging slows, and quality drops.

Also Read, Why Industrial Dehumidifiers Matter More Than You Think in Manufacturing Units

What Ideal RH Levels Look Like in Powdered Food Production?

Different powdered foods behave differently, but humidity affects all of them in some way — whether it’s spices absorbing moisture, whey powder forming lumps, or instant mixes turning sticky. The safest, most stable range for powdered food processing is:

30% – 45% Relative Humidity (RH)

This range keeps powders dry, free-flowing, and stable. Once RH rises above 50%, powders quickly start absorbing moisture from the air. That’s when clumping, sticking, and uneven flow begin.

Here’s what happens at different RH levels:

- Below 30% RH

Powders stay extremely dry but may generate static electricity. This rarely happens in Indian climates unless ACs are used heavily. - 30% – 45% RH (Ideal Zone)

Free-flowing powders, smooth operation, accurate filling, no lumps. - 45% – 55% RH

Slight stickiness, uneven flow, small clumps forming inside hoppers and packing machines. - Above 55% RH

Rapid clumping, caking, machine choking, higher risk of microbial growth.

Maintaining this ideal RH helps stabilize:

- Texture

- Particle size

- Pouring consistency

- Product weight

- Shelf life

This is why powdered food manufacturers need dehumidifiers working continuously — not seasonally — to keep RH stable throughout storage, processing, and packaging.

Why Are Dehumidifiers Better Than Temporary Fixes?

Manufacturers often try makeshift fixes when humidity rises, especially during monsoons. But these solutions don’t address the root cause.

Here’s why temporary measures fail — and why dehumidifiers consistently work.

❌ Air Conditioners

ACs cool the air but don’t remove enough moisture. The air “feels” dry but RH remains high and invisible.

Result: Powders still clump.

❌ Exhaust Fans

They push humid indoor air outside but pull in more humid outdoor air.

Result: RH becomes worse instead of better.

❌ Silica Gel or Desiccant Packs

Useful for small containers — not industrial spaces.

Result: They saturate within hours and offer no real control.

❌ Heating or Blow Dryers

Raises temperature unnaturally and can alter powder composition.

Benefits of Dehumidifiers for Powdered Food Producers

A well-controlled humidity environment creates a ripple effect across your entire production line. Here are the biggest benefits:

1. Smooth, Free-Flowing Powders: No clumps, no sticking, no caking — powders retain their natural texture and movement.

2. Faster, Cleaner Packaging: Flowing powders move quickly through machines, reducing:

- Jams

- Stoppages

- Overflows

- Machine wear

Your entire packaging line becomes faster and more predictable.

3. Accurate Weight in Every Packet: Consistency in powder flow means:

- Correct dosing

- No underfilling

- No overfilling

- Better compliance

4. Longer Shelf Life: Low humidity slows microbial activity, prevents spoilage, and maintains product freshness.

5. Lower Wastage & Higher Profitability: You avoid:

- Rejected batches

- Reworks

- Quality complaints

- Material loss

This directly improves your bottom line.

6. Better Product Consistency: From taste to texture to appearance — everything remains uniform across all batches and seasons.

7. Stable Machinery Performance: Machines run smoothly because powders don’t clog nozzles, valves, or lines.

What to Look for in a Dehumidifier for Powdered Food Production?

To ensure the best protection against moisture problems in powders, choose a system that offers:

- Compatibility with food-grade environments

- Suitable capacity for room size

- Low energy consumption

- Continuous drainage

- Hygienic design

- High durability

- Consistent RH control

Final Thoughts

Moisture doesn’t give warnings.

It slips into your facility slowly and starts affecting raw materials, blends, and packaging lines. Small clumps turn into large losses. Packaging delays become customer complaints. And every season, humidity returns — stronger than before.

This is why powdered food manufacturers need dehumidifiers as part of their facility planning. They help maintain ideal RH levels, prevent clumping, protect product quality, and keep every step of production running smoothly and predictably.

Humidity is unpredictable, but your production doesn’t have to be.

Credence offers industrial-grade dehumidifiers designed specifically for sensitive segments like powdered food, spices, dairy powders, instant mixes, and nutraceuticals.

Our systems help maintain ideal RH levels, prevent clumping, protect product texture, and keep your production lines moving without interruption.

If moisture is repeatedly affecting your output, we can help you create a stable, efficient, and complaint-free production environment.